- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Reject Conveyor Series

Reject Conveyor Series

The unit installed after AOI for separated NG board for visual inspect and good board will pass through without stopping.

Benchtop Repair Station BRS-100

Benchtop Repair Station BRS-100

● This system is used to communicate with BA-400. THT Solder Joint Automated Inspection System, use light spot……

MAS-i22/1 Inline selective soldering Machine

MAS-i22/1 Inline selective soldering Machine

This machine is designed with a dual rail conveyor (W580xL508mm), four individual solder pots, and can solder four boards simultaneously. It also can expand to solder six pots.

Telescopic Conveyor Series

Telescopic Conveyor Series

The unit provides a 'normal open' passage in a PCB assembly line. An integrated conveyor segment slides across the opening to deliver PCB to downstream machine.

MAS-i24/1 4 pots selective soldering

MAS-i24/1 4 pots selective soldering

MAS-i24/1 is the machine designed for below products: 1. High output requirement! Machine designed with single lane conveyor (Max W508xL508mm), 4 individual solder pot, can solder for 4 boards at same time. 2. Heavy lo……

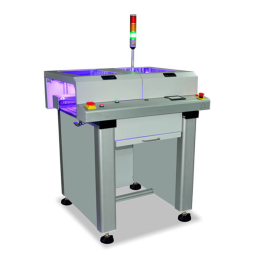

Coating Conveyor Series

Coating Conveyor Series

This unit is used as a visual inspection station for operators controlling the boards right after a conformal coating line.

Compact Flexible Mounter CM-S4

Compact Flexible Mounter CM-S4

CM-S4 Adopt step-servo motor and 4 mounting spindle, with stage vision system which is capable to mount 0201 chips to the largest 30mm IC. it is very suitable for Small batch production; University teaching use; R&D cus……

MAS-i36/1 Inline selective soldering Machine

MAS-i36/1 Inline selective soldering Machine

MAS-i36/1 layout: MAS-i36/1 General Explanati……

Manual Lift Gate Conveyor Series

Manual Lift Gate Conveyor Series

By manual lifting the conveyor section, access is gained to the rear of the line.

Advanced Flexible Mounter CM-S8

Advanced Flexible Mounter CM-S8

CM-S82 Adopt linear motor and 8 mounting spindle, with flying vision the efficiency of mounting and accuracy is greatly improved, it is applicable to 0402 chips to the largest 30mm IC.

High Speed LED&Lens Mounter CM-V8

High Speed LED&Lens Mounter CM-V8

CM-V8 Equipped with 8 spindles * 1 gantry and X/Y linear motor which makes machine running fast and stably, max LED mounting speed can readh 40,000 pcs/Hour, Lens mounting speed can reach 18, 000 pcs /hour.

High Speed LED Mounter CM-S36

High Speed LED Mounter CM-S36

CM-S36 Equipped with 18 spindles * 2 gantry and linear motor which makes machine running fast and stably, max mounting speed can readh 170,000 pcs/Hour.