- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Flexible placer SM481 PLUS

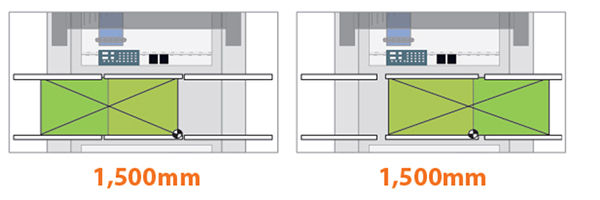

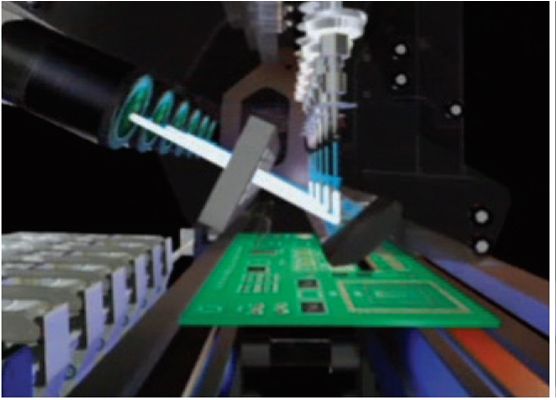

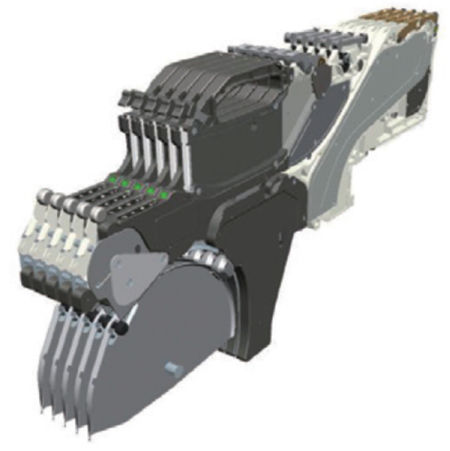

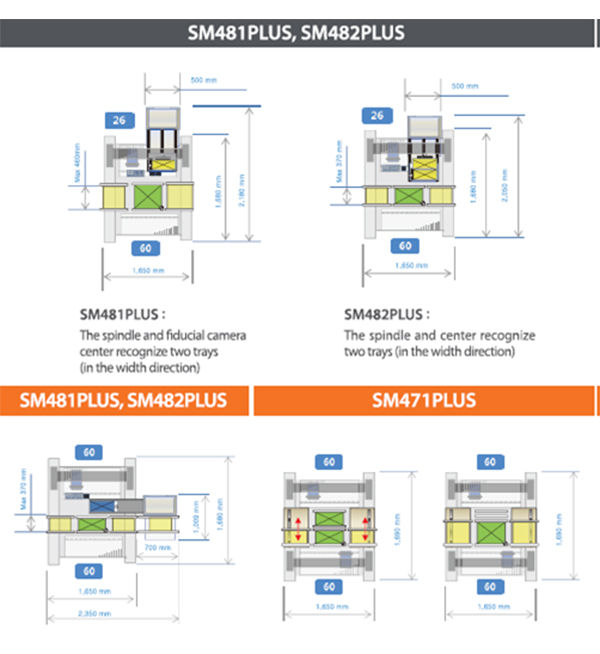

The SM481PLUS can perform high-speed placement of chips at 40,000CPH and QFPs at one per 1.1 seconds, respectively (each at optimum speed) by applying the on-the-fly recognition technology patented by techwin, which enables component placement at the highest speed among all medium speed component placers. with one-gantry structure having a high-speed piano head with 10 nozzles, the machine can be oerated with minimum manpower using one side of the machine. Being able to produce long boards with lengths of up to1,500mm, the machine boasts of its applicability to the largest PCBs among SM series component placers.

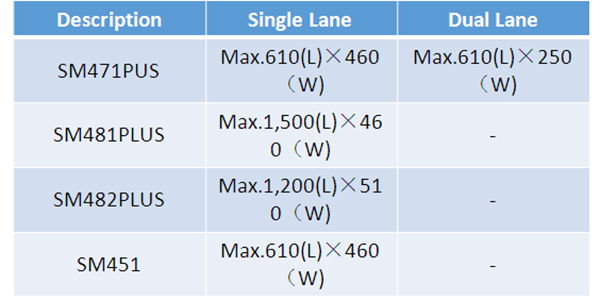

Available Options

Flexible placer SM481 PLUS

×1,500mm long board Two-staged placement using an extended conveyor allows production of long boards with lengths of up to 1,500mm. (The SM482PLUS can produce boards with lengths of up to 1,200mm) One-Side Operation With single gantry and single lane structures optimized for machine operation using only one side of the mchine, the production area and manpower can be utilized efficiently. |

|

Production speed and component coverage suitable for general-purpose high-speed placement General-purpose high-speed machine among SM series component placers, which applies a high-speed piano head with 10 nozzles and an option for an upward camera. |

|

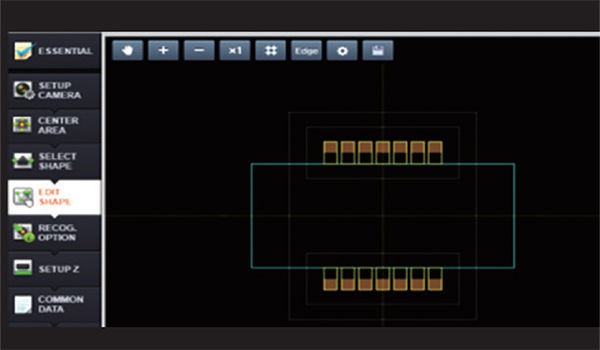

| Panorama View Function Since large-sized components are not viewed in one screen, it is hard to adjust their pickup or placement positions. In order to remove such inconvenience, the panorama view function is added to allow large components to be viewed within the FOV of a camera. |

|

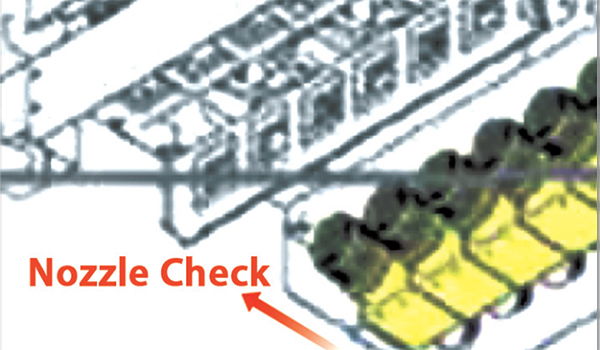

| Component Monitoring before/after Plancement Checks for nozzle contamination during production to prevent non-insertion and dumping of a large number of components in advance, ensuring high quality production. Time of inspection-Before/after ANC; before/after component placement; and after component dumping |

|

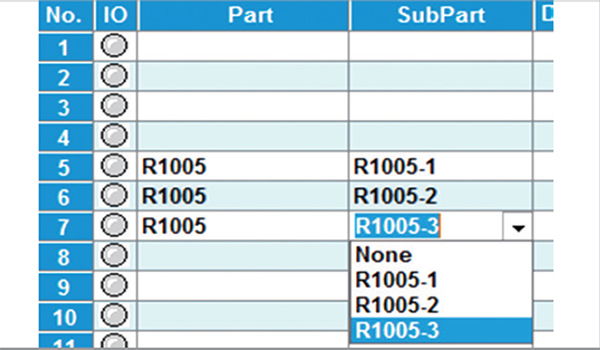

Multi-Vendor Component Management Function When the same components are supplied from different component supply devices, this function allows components to be use without changing a PCB file and downloading a new PCB file. |

|

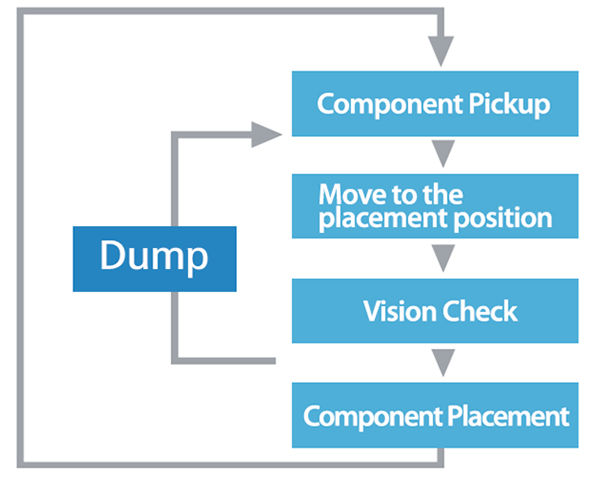

| On-the-fly Placement Method Owing to techwin's own On-the-fly image recognition technology which allows component recognition without stopping while moving after component pickup, placement speed is maximized by minimizing the moving time between the pickup position and placement position and reducing the recognition time to zero. Added a new function maximizing the operational convenience of customers. |

|

|

| Easy Component Registration New Part Editor A Drag & Drop component registration system, allowing registration of component informatic recognition and rotation by simply clicking the mouse. (When applying Elite2) In addition, user convenience is further reinforced by unifying the on-line/off-line comvenience is further reinforced by unifying the on-line/off-line component registration systems. |

|

| Mixed Use of Electric Feeder and Pneumatic Feeder Mixed use of electric and pneumatic feeders in the same feeder base is available for SM series component placers. The investment in production can be minimized by using these feeders along with existing feeders. |

|

| The highest applicability to long and large PCBs among machines of the same class |

|

Features | ||

NO. | Performance | Parameter |

1 | Placement Speed | Chip 40,000CPH(Optimal) |

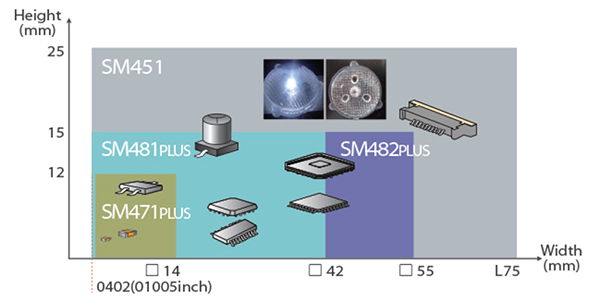

2 | Applicable Component | 0402(01005inch)~ Max. 42mm(h15mm) |

3 | Placement Accuracy | ±40μm@±3σ/Chip ±30μm@±3σ/QFP |

4 | Applicble PCB | L460×W400×1Lane (Standard) L1,500×W460×1Lane(Option) |

SM481 PLUS Specification | |||

Model | SM481 PLUS | ||

Alignment | Flying Vision +Stage Vision(Option) | ||

Number of Spindles | 10 Spindes×1Gantry | ||

Placement Speed | 40,000 CPH (Optimum) | ||

Placement Accuracy | Chip | ±40μm@μ±3σ | |

| QFP | ±30μm@μ±3σ | ||

Component Range | Flying Vision | 0402(01005)~16mm IC Connector (Lead Pitch 0.4mm) BGA, CSP(Ball Pitch 4.0mm) | |

| NA | |||

| Stage Vision | ~ 16mm IC, Connector(Lead Pitch 0.3mm) BGA, CSP (Ball Pitch 0.4mm)~□ 32mm IC, Connector (Lead Pitch 0.4mm) BGA, CSP (Ball Pitch 0.5mm) | ||

| ~ 32mm IC, Connector(Lead Pitch 0.4mm) BGA, CSP (Ball Pitch 0.5mm)~□ 42mm (H12mm)IC, Connector (Lead Pitch 0.5mm) BGA, CSP (Ball Pitch 1.0mm) | |||

| Max.Height | 10mm(Option 15mm) | ||

| Min. | 50(L)×40(W) | |

| Max. | Single Lane | 460(L×400(W) 510(L)×460(W)Option 610(L)×510(W)Option Max. 1,500(L)×460(W)(Option) | |

| Dual Lane | NA | ||

| PCB Thickness | 0.38~4.2 | ||

Feeder Capacity (8mm standard) | 120ea/112ea(Dacking Cart) | ||

Utility | Power | AC200/208/220/240/380/415V(50/60Hz, 3Phase) | |

| Max3..5kVA | |||

| Air Consumption | 0.5~0.7MPa(5.0~7.0kgf/cm²) | ||

| 150Ne/min | |||

| 50Ne/min(vacuum pump) | |||

Mass(kg) | Approx.1655 | ||

External Dimension (mm) | 1650(L)×1680(D)×1530(H) | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 review for Donec eu furniture

Related Products

Advanced Flexible Mounter CM-S8

- Model: CM-S8

High Speed LED Mounter CM-S36

- Model: CM-S36

Juki RS-1

- Model: RS-1

Odd shape component placer SM451

- Model: SM451

Multi-functional placer SM482 PLUS

- Model: SM482 PLUS

Add a review

Your email address will not be published. Required fields are marked