- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

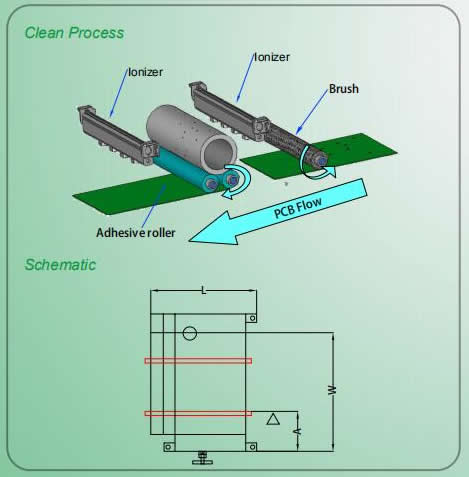

Single Side PCB Cleaner Series

This unit can remove glass fiber, dust particles, etc. on top surface of PCB before solder paste printing, and improve production yield. Especially suitable for PCB which is mounted extremely small components.

Available Options

Single Side PCB Cleaner Series

×

|

Single Side PCB Cleaner Series Features : |

|

● Pannasonic PLC Program control. |

|

● On-line automatic clean. |

|

● All types of dust can be removed. |

|

● Adhesive clean roll removes all dust from rolls. |

|

● Ionizer removes electric static on the PWB. |

|

● Draw-out design for Easy changing of adhesive rolls. |

|

● Preset number of PCB & pre-warning counter to purge adhesive rolls. |

|

● User friendly touch screen control panel. |

|

● SMEMA compatible. |

|

Single Side PCB Cleaner Series Specification : |

||||

|

Model |

SPC250M |

SPC330L | SPC390LL | SPC460XL |

|

Machine Dimension (LxWxH) |

550x650x1350(mm) |

550x680x1350(mm) | 550x780x1350(mm) | 550x850x1350(mm) |

|

Weight |

170kg |

185kg | 220kg | 260kg |

|

PCB length |

50mm-330mm |

50mm-450mm | 50mm-530mm | 50mm-530mm |

|

PCB width |

50mm-250mm |

50mm-330mm | 50mm-390mm | 50mm-460mm |

|

PCB Thinckness |

0.6mm-4.5mm |

0.6mm-4.5mm | 0.6mm-4.5mm | 0.6mm-4.5mm |

|

Fixed rail to front dimension(A) |

190mm |

190mm | 190mm | 190mm |

|

Single Side PCB Cleaner Series Technical Specifications : |

|

● Transport height: 910mm ±30mm |

|

● Transfer direction: Left to right |

|

● Operation side: Front of the machine |

|

● Fixed rail: Front of the machine |

|

● Interface: SMEMA |

|

● Conveyer concept: ESD flat belt |

|

● Belt speed: 0.5-20m/min adjustable |

|

● PCB edge support: 3mm |

|

● Power supply: 230 VAC/50 Hz/1 Ph |

|

● Power consumption: 150VA max. or specify |

|

● Air supply: 4-6 bar |

|

● Air consumption: 2 ltr/min max. |

|

● Cycle time: ±8 seconds |

Double side PCB processing.

Automatic conveyor width adjustment.

Other options available on request.

0 review for Donec eu furniture

Related Products

Inspection Conveyor Series

- Model: CYB

High Version Conveyor Series

- Model: CYX

High Version Reject Conveyor Series

- Model: CYCX

Reject Conveyor Series

- Model: CYC

Telescopic Conveyor Series

- Model: CYT

Add a review

Your email address will not be published. Required fields are marked