- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

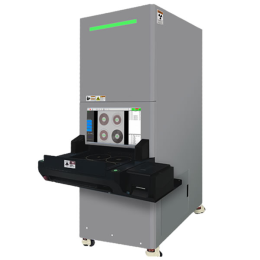

Detection Equipment-CX-3500

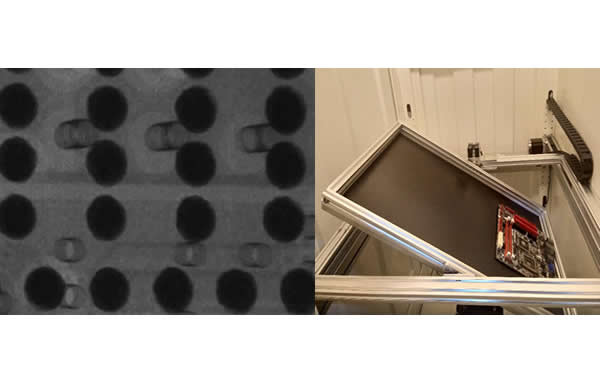

CX-3500 is use to examine internal solder joints, BGA, IC and other complex components.It adopts the structure of high resolution enhanced screen and sealed microcoking X ray tube combination, through X-ray non-destructive fluoroscopy, real-time observation of clear pictures. In addition, the powerful software measurement function makes the inspection efficiency greatly improved.

Available Options

Detection Equipment-CX-3500

×|

|

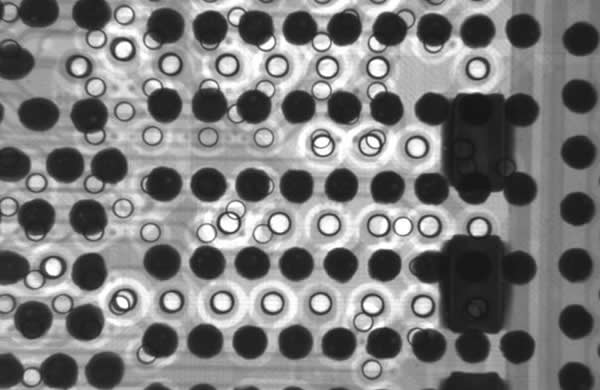

● Dimensional view of solder balls |

|

|

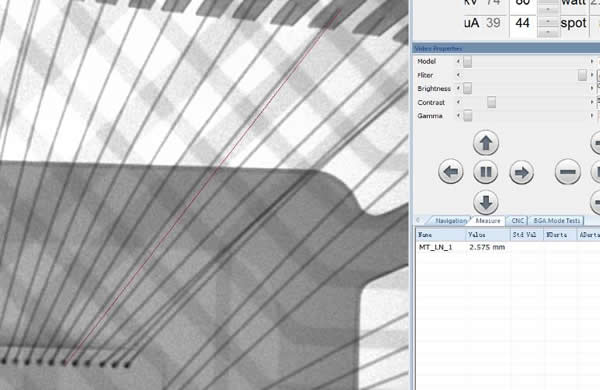

● Size measurement:Distance, radian,slope,Angle etc. |

|

|

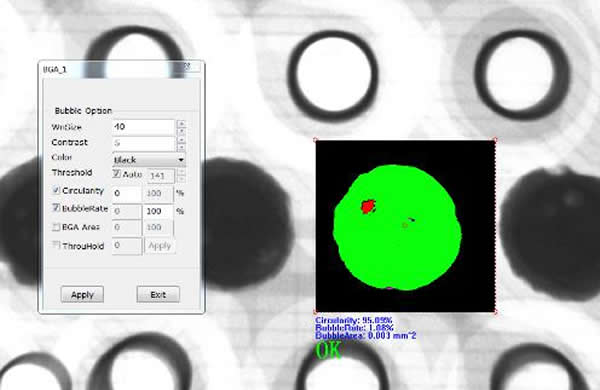

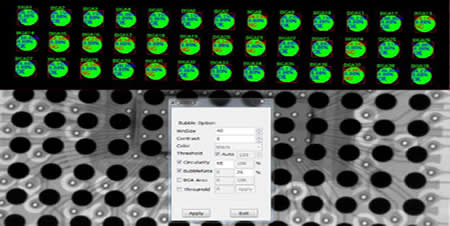

● Auxiliary tool: the circularity, bubblerate, BGA area and throuhold of solder joints in the selected area can be calculated.

|

|

|

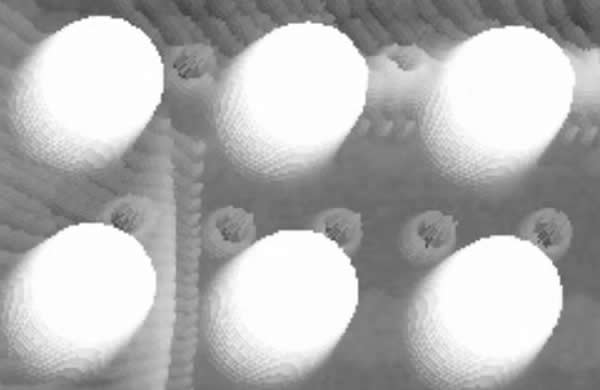

● Simulation 3D:BGA and other 3D effects display |

|

|

● The Max tilt angle can reach 45 ° |

X-Ray Detection Equipment- CX-3500

|

1. Foreign original imported micro focal X-ray tube (100Kv closed tube), high sensitive image intensifier, 2 million high-speed industrial digital CCD camera. Can detect 5 micron sample, image display effect is good. |

|

2. High magnification and system magnification can adjustable, easy to detect tiny defects, quick detection. |

|

3. System navigation map, fast navigation precise positioning. |

|

4. Five-axis linkage, CNC batch automatic detection function, suitable for much mass detection, high detection accuracy. |

|

5. LCD screen for 24 - inch digital image, super - large hd image display. |

|

6. Multi-functional software system. |

|

7. All sealed lead cabinets meet the international standard for X-ray safety. |

|

X-Ray Detection Equipment- CX-3500 |

||||

| Hardware |

X-Ray Tube |

Tube Style |

sealed tube |

No need for vacuum, no after sales overhead |

| Image Intensifier | Tube voltage | 100KV | Penetrates heat sink | |

| Tube current | 0.15mA | Great Power | ||

| Focus size | 5um | Excellent resolution | ||

| Cooling mode | Air cooling | no maintenance | ||

| Resolution | 110 lp/cm | High Resolution | ||

| Geometric magnification | 400X | identifies smallest void | ||

| System magnification | 1200X | identifies smallest void | ||

|

Operation stage |

Two operation model options: mouse, keyboard |

|||

|

Detection area |

600mm * 410mm (Large size customization) |

It is suitable for large or multi - block PCB to improve the detection efficiency greatly. | ||

|

Machine |

X Axis | 500mm | It is suitable for large or multi - block PCB to improve the detection efficiency greatly. | |

| Y Axis | 410mm | |||

| Z Axis | 325mm | |||

| Dimension | 1170*1090*1860mm | |||

| Power supply | AC110-230VAC,50/60Hz | Universal | ||

| Computer | Brand | Lenovo&HP | The after-sales service promised by the company. | |

| Operation System | Windows®XP or Windows® 7 | Genuine software | ||

| Display | 24”LCD | Large screen, full screen hd display image. | ||

| CPU | Dual core | |||

| Safety | Radiation Safety Standard | <0.5mR/hr | ||

| Safety interlock function | Observation window, side door, backdoor position all set high sensitivity limit switch, once opened, X-ray tube immediately automatic power off, guarantee safety. | |||

| Electromagnetic swift protecting function | The window door is equipped with an electromagnetic lock switch. When the X-ray is opened, the window door cannot be opened. | |||

| All electronic parts are strictly protected | Protect electrical and air life. | |||

| Software | Automatic judgment of welding defects. | BGA Air bubbles | Preset NG image BGA parameters, automatic comparison and identification through software. | |

| BGA Cold welding | Preset NG image BGA parameters, automatic comparison and identification through software. | |||

| BGA short circuit | Preset NG image BGA parameters, automatic comparison and identification through software. | |||

| BGA False welding | Preset NG image BGA parameters, automatic comparison and identification through software. | |||

| Graph | Auxiliary judgment BGA false welding. | |||

| Self protecting function of x ray tube | The software and equipment have no operation for ten minutes.The X - ray tube is automatically cut off into self - protection. | |||

| Working Environment |

Safety Operating Temp |

0-40℃ | No special isolation, no conductive dust. | |

|

Warranty |

One year, parts and labor | Except for man-made damage and force majeure. | ||

| Measurement functions | Size measurement | Distance, radian, slope, Angle, etc. | ||

| Area measurement | Setting area size standard, NG product prompt function. | |||

| Simulation 3D | BGA and other 3D effects display. | |||

| Bubble measurement | Single plant and multi-strain measurement can be automatically measured by preset bubble standard area. | |||

|

Software service |

Lifelong maintenance and upgrade. | |||

0 review for Donec eu furniture

Related Products

Merlin A-400P Offline Automated Inspection System

- Model: Merlin A-400P

Falcon SA-510F SMT Component Automated Inspection System With Flipper

- Model: Falcon SA-510F

X-Ray Counter SoYi-C3

- Model: SoYi-C3

X-Ray Counter SoYi-C2

- Model: SoYi-C2

SA-500 SMT Component Automated Inspection System

- Model: SA-500

Add a review

Your email address will not be published. Required fields are marked