- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Pneumatic Stencil Cleaner HC-6S

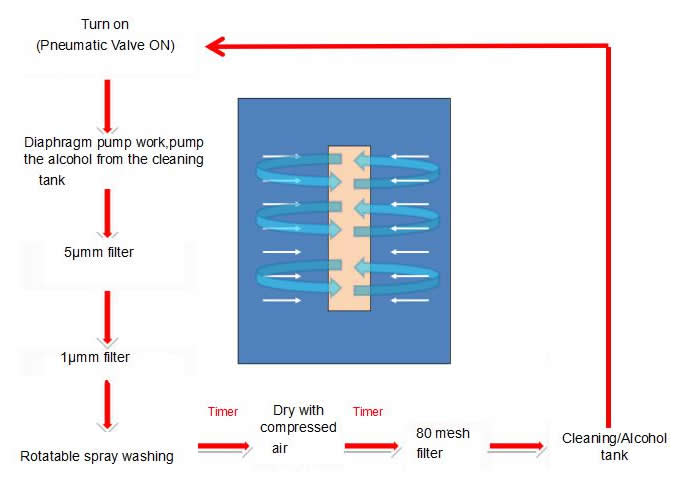

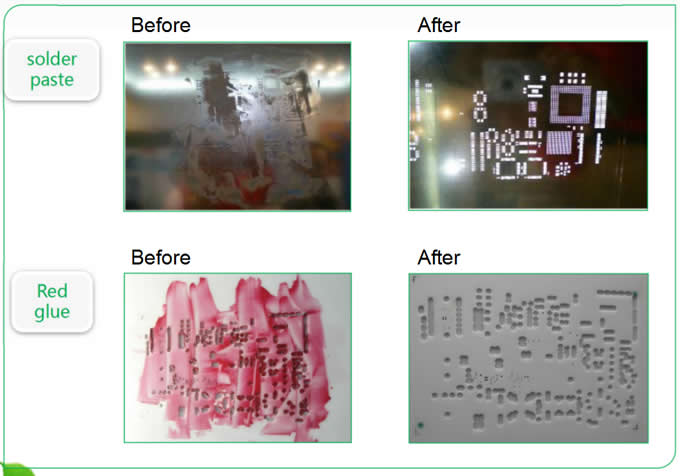

HC-6S peumatic stencil cleaner is suited for solder past, red glue on stencil cleaning, it adopt full pneumatic control without power supply to avoid fire risk. 3 stage precision filtering system greatly prolong cleaning liquid service life. High quality parts ensures long service life of machine.

Available Options

Pneumatic Stencil Cleaner HC-6S

×|

Waste water recycling and reuse by filter system |

|

|

|

|

|

Inlet air pressure regulator, which filter the oil and water in the compressed air. |

|

|

Stainless steel liquid tank with level display, which can contain various types of acid and alkali resistant cleaning liquid. |

|

|

Germany made Hengstler pneumatic timer. |

|

|

USA made Ingersoll RandIp neumatic diaphragm pump. |

|

|

10 μm filtering screen(filter impurities and labels). |

|

|

5 μm filter (filtering tiny particles and solder paste). 1 μm (filter micro particles and rosin). |

|

|

Adjustable holder design fixing the stencil firmly. suitable for different sizes of stencil cleaning. Maximum size 750X750X40 (mm). Removable chute: easy to maintain, clean and maintain. |

|

|

S-type exhaust pipe design effectively reduce vaporized liquid. |

|

HC-6S Pneumatic Stencil Cleaner Features: |

|

● HC-6S peumatic stencil cleaner is suited for solder past, red glue on stencil cleaning, and squeegee cleaning etc. |

|

● Full pneumatic control without power supply to avoid fire risk. |

|

● High precision 3 class filtering system ensure cleaning quality. |

|

● Cleaning plus air drying process to ensure cleanliness. |

|

● The liquid pressure can be displayed by the hydraulic gauge on the operating panel. |

|

● The machine is made of 304 stainless steel, which is durable, acid resistant and alkaline resistant. |

|

● One-button operation, easy operation to complete cleaning, air drying process. |

|

● Equipped with high quality parts such as USA made Ingersoll RandIp neumatic diaphragm pump, Germany made Hengstler pneumatic timer, which ensure long service life of machine. |

|

HC-6S Pneumatic Stencil Cleaner specification: |

|

|

Model |

HC-6S |

|

Stencil size |

Max L750×W750×H40(mm) |

|

Cleaning fluid capacity |

40L(Max) |

|

Optimum liquid usage |

35L |

|

Cleaning method |

360° rotating cleaning fluid injection and high pressure air injection (cleaning and drying) |

|

Cleaning time |

2-5minutes(conventional process) |

|

Drying time |

2-5minutes(conventional process) |

|

External air pressure |

0.45Mpa~0.7Mpa |

|

Filtering system |

Three-stage filtering |

|

Level 1 filter |

10μm filtering screen(filter impurities and labels) |

|

Level 2 filter |

5μm(filtering tiny particles and solder paste) |

|

Level 3 filter |

1μm (filter micro particles and rosin) |

|

Exhaust port size |

Φ120× H40(mm) |

|

Air consumption |

400-600L/Min |

|

Machine net weight |

200kg |

|

Machine size(mm) |

L945×W650×H1645(mm) |

|

HC-6S Pneumatic Stencil Cleaner configuration: |

|

HC-6S Pneumatic Stencil Cleaner includes: |

|

● HC-6S Pneumatic Stencil Cleaner*1set |

|

● 1μm filter core*1pcs |

|

● 5μm filter core*1pcs |

|

Optional configuration: |

|

● 5μm filter (consumable parts, service life: around 1 months) |

|

● 1μm filter (consumable parts, service life: around 1 months) |

|

● 10μm filtering screen (consumable parts, service life: around 3 months) |

|

● Vacuum filter (consumable parts, service life: around 3 months) |

Add a review

Your email address will not be published. Required fields are marked